What You Need To Know About Roof Flashing

∙ min read

Many homeowners are unaware of the importance of maintaining roof flashing after a home build or renovation project. As a fundamental component, an essential part of your roof to preserve are the transition points, where the ceiling, walls, and other structures meet. Flashing is installed around these transition points to prevent leaks and other foreign debris from entering your home. Flashing creates an airtight seal when installed appropriately, but it must be maintained to keep functioning correctly. Unfortunately, many people neglect to service this area, and the result is often a roof leak.

Here is everything you need to know about metal roof flashing.

What Is Roof Flashing?

Roof flashing can be described as a thin barrier placed on your roof surface to prevent mold and water damage issues. The layer is resistant to several weather elements, including wind, rain, and snow. Roof flashings are made of various materials, including copper, lead, steel, or aluminum.

What Is the Function of Roof Flashing?

Flashing is used as an enclosure to connect joints in walls or roofing applications. This enclosure performs a vital function to prevent moisture from leaking into the roofing materials; flashing works by collecting excess water and guiding it away from the installed location.

Roof structures such as vents, chimneys, and skylights should also be surrounded by flashing to prevent moisture from entering the home. Flashing should be maintained but is unlikely to malfunction if it is installed correctly and preserved. You can start with a roof inspection; this way, you will know if there is damaged flashing and what you will need for your flashing repair.

Types of Roof Flashing

Different types of flashing may be used depending on the location and the roof types. These are the main types of flashing used on homes today:

-

Continuous flashing: commonly referred to as apron flashing, continuous flashing is adequate because it acts as a metal barrier across the shingles. It is made up of a long, solitary piece of steel that directs water down to the shingles below the material. Continuous flashing is sturdy but is not flexible as your home contracts in the changing seasons. Joints should be installed to the flashing so it can expand and contract with the home.

-

Base flashing: certain roof features cannot be accommodated with one piece of roof flashing. Some roof aspects, such as chimneys and vents, require two separate pieces of flashing. Installing two individual parts ensures rain is directed correctly downwards. Two-piece flashing is beneficial because it naturally contracts and expands with weather and structural changes.

-

Counter flashing: used in conjunction with base flashing, counter flashing is installed on top of the second piece. Base and counter-flashing must always be used as a set.

-

Step flashing: sometimes referred to as rectangular flashing, step flashing is a long piece of metal with a 90-degree bend in the center. Multiple parts will often be installed in layers to ensure moisture is directed away from the walls of your home.

This is not a comprehensive list of all flashing types. Other variations may be used based on the location and style of your home. Consult with roofing professionals or your home builder to recommend the best kind of flashing to use.

Roof Flashing Materials

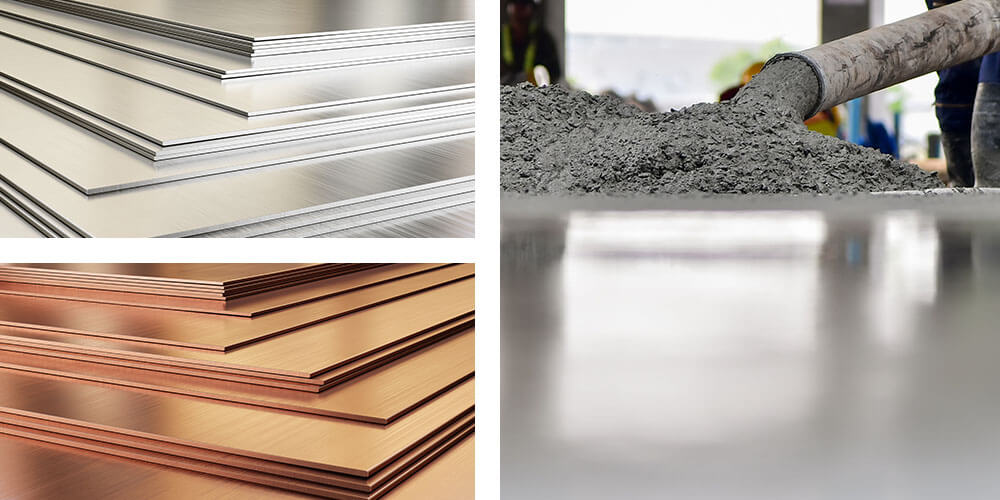

Roof flashing is made out of many different types of materials. The most common types of materials include:

-

Aluminum flashing: many roofing contractors prefer aluminum because it is lightweight. However, aluminum must be treated before use if used in conjunction with concrete because untreated aluminum will deteriorate if it touches certain alkaline surfaces. In coastal areas, aluminum should always be treated to prevent corrosion.

-

Copper flashing: copper is a popular material as it is highly durable and does not require a lot of maintenance. However, aluminum discolors easily and can tarnish quickly. Copper is commonly used around chimneys because of its durability.

-

Steel or metal flashing: steel is the most common type of material used for flashing. It is durable, flexible, corrosion-resistant, and has aesthetic appeal.

-

Concrete flashing: occasionally, flashing may be constructed from an alternative material, including concrete. While not commonly used, concrete can be an effective flashing material for certain types of structures.

Building codes and specific community associations require homeowners to use a particular roof flashing material. Make sure and check with your local entities because buying a specific type of flashing. Always check with local codes to ensure you are following all laws.

You should consult with a roof repair specialist or roofing contractor when it comes to roofing flashing maintenance. Some experts recommend a roof inspection annually, while others only advise having an assessment once every few years. If you are working on a complete roof replacement, always consult with a specialist about the best roofing system for your home.

Work With an Expert

Max Warehouse is a specialized retailer that carries everything you need to build, clean, and maintain your home or business. We sell a variety of roof flashing materials and accessories. Contact us today to find the perfect roofing material for your home or business.

Shop Roof Flashing Products Today